Quality Control

Plan inspections, execute tests, manage defects, and track product quality in real-time to easily control quality outcomes at every stage of manufacturing.

What is DELMIA Apriso Quality Control Software?

DELMIA Apriso Quality Control (QC) is the software that puts you back in control of your quality program – both at the plant level and across the distributed environment many manufacturers now operate. It provides guided and enforced quality testing, 3D defect tracking, issue management, Statistical Process Control (SPC) and full integration with production, maintenance and warehouse through DELMIA Apriso's unified database to improve traceability, efficiency, and quality.

Seamlessly Manage Product Quality with DELMIA Apriso QC

Users can seamlessly plan inspections, execute tests, manage defects, and track product quality in real-time with DELMIA Apriso Quality Control software. Inspection tasks and step-by-step quality instructions are seamlessly integrated into the operator's unified interface for production, maintenance or warehouse processes. Value is realized when businesses are assured that product quality is upheld or enhanced, with step-by-step directed execution provided through in-line checklists, work instructions, safety protocols, or documentation.

In addition, our manufacturing quality control software can be modeled and simulated in the DELMIA Product and Production Systems virtual twins, ensuring the most effective and efficient quality processes. It also provides sense computing capabilities such as Augmented Reality for quality inspections and it includes artificial intelligence for automated quality inspections and predictive quality.

Key Features of Manufacturing Quality Control Software

- 3D Visual Quality Defect Tracking

- Containment Management

- Issue Management

- Quality Planning

3D Visual Quality Defect Tracking

Speed up defect reporting with greater accuracy and adds a powerful new visual level to analysis. It allows users to report visual quality defects directly on 3D models with greater accuracy. The 3D model can be imported along with product information, making it easier to create and maintain product visualizations in a 3DXML format that eliminates the need to maintain multiple 2D product images for visual defect reporting. It is intuitive and easy-to-use for quality inspectors, production line, warehouse workers and others responsible for product quality, and it provides clarity to Engineering if it is determined that quality issues are being driven by a design issue. The 3D product image can be sourced from a variety of applications, including PLM, CAD drawings, etc. to enable a more complete and accurate quality analysis.

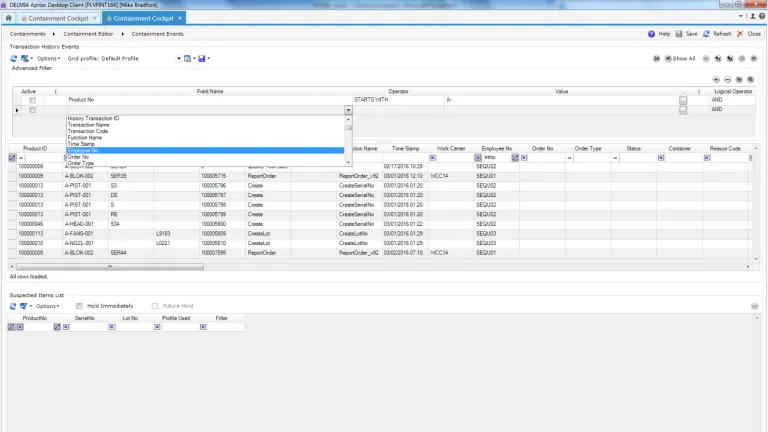

Containment Management

Containment Management improves operational performance by reducing the risk and impact if, in spite of all quality efforts, a quality issue does occur. It enables users to quickly, easily, and cost-effectively identify and isolate all affected materials, Work-in-Process (WIP), and finished goods across your operations. This gives users visibility and control to avoid costly warranty charges or product recalls and prevent quality issues from reaching customers and negatively affecting brand image. Containment management can be a critical element to help address regulatory compliance requirements, resulting in improved product quality to achieve and sustain manufacturing operations excellence.

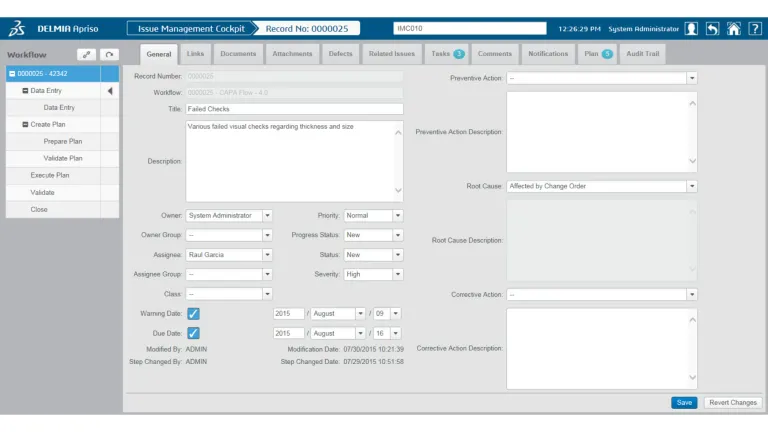

Issue Management

Issue Management is a comprehensive enterprise solution leverages the DELMIA Apriso unified data model and spans the wide footprint of manufacturing. It enables the user to configure a formal issue management process, such as 8D or CAPA, to ensure all required corrective action steps are taken, all required personnel are involved and any required approvals are gathered. It allows quick identification of root causes and corrective actions, accelerating resolution on any event that might disrupt or hinder objectives – from maintaining high quality standards to implementing continuous improvement initiatives across any part of manufacturing operations.

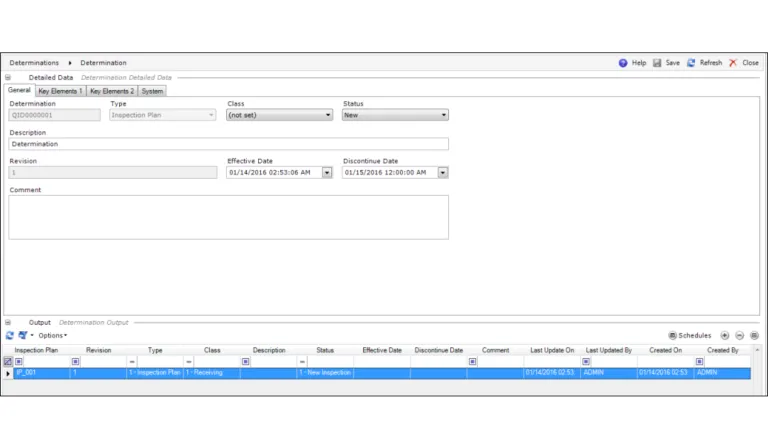

Quality Planning

Quality Planning provides powerful capabilities to plan quality testing and inspection for one plant or many, ensuring manufacturing quality assurance programs are implemented and tracked consistently across the enterprise. Create plans in DELMIA Apriso Quality Planning, in DELMIA Process Planning using PFMEA and Control Plans, or in an external system. Our comprehensive quality assurance software manages the master planning data. It controls execution on the plant floor, tightly coordinated with production, maintenance and warehouse operations through the DELMIA Apriso unified database. It supports schedules based on time, quantity, or events and enables the creation, maintenance and execution of Sampling Procedures, supporting lot-by-lot product inspections compliant with the ISO-2859 standard.

Key Benefits of DELMIA Apriso Quality Control

Continuous Improvement

3D VQDT enables continuous improvement, provides rapid response to market changes, clarifies communication between manufacturing and engineering, and links the full 3D model to the product record.

Increase Customer Satisfaction

Containment Management improves customer satisfaction, reduces risk to brand image, greatly reduces time & effort to identify affected part and minimizes production and customer disruptions.

Achieve Operational Excellence

Issue Management ensures proper issue management procedures are followed, simplifies issue resolution and prevention, enhances operational excellence and reduces the cost of quality.

Minimize Disruptions

Quality Planning minimizes shop floor operations disruptions, ensures all required inspections are performed in production, combines key capabilities, and creates an environment for quality control perfection.

Start Your Journey

The world of quality management system is changing. Discover how to stay a step ahead with DELMIA Apriso Manufacturing Quality Control software.

FAQ about Manufacturing Quality Control Software

Also Discover

Learn What DELMIA Can Do for You

Speak with a DELMIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right DELMIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering