Warehouse

Synchronize inventory management with production through a comprehensive warehouse management system for real-time visibility and seamless operations.

What is DELMIA's Warehouse Management System Software?

DELMIA Apriso Warehouse goes beyond traditional WMS systems by providing a unified solution for synchronizing inventory management with production, resulting in vastly improved inventory accuracy and manufacturing efficiencies.

Synchronize inventory management with production through a comprehensive warehouse management system that delivers real-time visibility, enhanced efficiency and seamless operations across your entire supply chain.

What is the Value of DELMIA Apriso WMS Solution?

DELMIA Apriso Warehouse Management System revolutionizes operations with its advanced warehouse management system software. It delivers comprehensive, real-time visibility and historical analytics into warehouse performance both within individual facilities and across multiple plants. This powerful WMS solution monitors all warehouse activities, including internal operations such as picking and kitting, as well as external-facing operations like vendor and customer interactions.

The Warehouse Intelligence Pack offers pre-configured inventory cost and performance analytics, reports, dashboards and Key Performance Indicators (KPIs), providing ready-to-use, warehouse-based reporting and analytics covering more than 45 indicators including inventory accuracy, warehouse utilization and response-time reporting.

Key Features of DELMIA Warehouse Management System Software

- Just-in-Sequence

- Warehouse Operator Role

- Warehouse Supervisor Role

- RFID

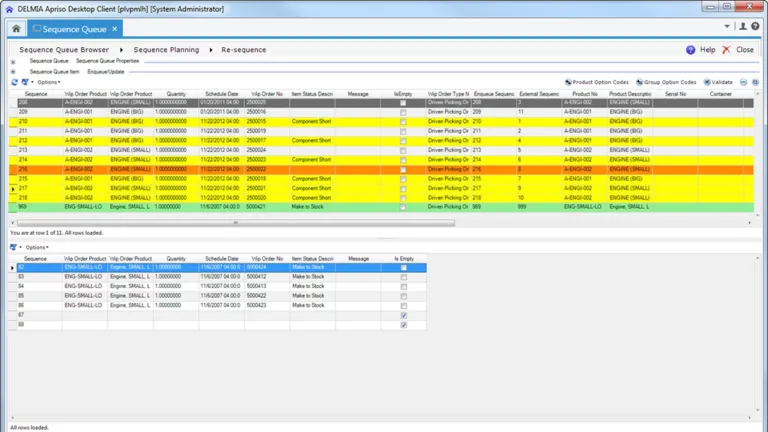

Just-in-Sequence

DELMIA Apriso Production and DELMIA Apriso Warehouse Management System software work together to enable just-in-time manufacturing, and sequenced manufacturing, assembly, and shipping to eliminate idle inventory, reduce waste and increase efficiency. These techniques improve inventory accuracy and achieve a lean material flow for greater inventory management control. It allows parts and sub-assemblies to be delivered to assembly lines in sequence to match assembly sequences, supporting in-line vehicle sequencing and just-in-time inventory, and resulting in balanced workloads and reduced WIP and lead times. It can also help manage sequence exceptions – at both the assembly line and the feeder lines – when issues like quality problems or equipment failures force immediate changes to the planned sequence.

DELMIA Apriso Warehouse Just-in-Sequence supports ship-to-sequence processes and includes an out-of-the-box sequence board where planners can adjust schedules in real-time, inserting and removing items to adapt to changes in demand and shop floor events.

Warehouse Operator Role

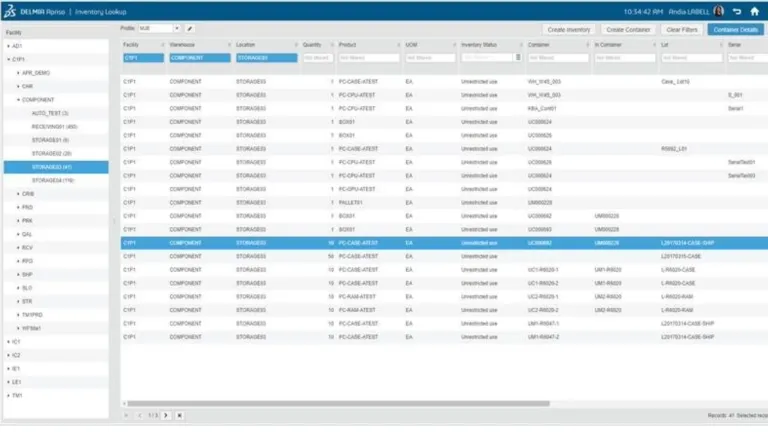

Warehouse Operator Role provides immediate insight into the shop floor, conducts inventory tasks, monitors incoming materials, and makes operations decisions via Android or IOS scanners. It provides directed picking based on LIFO, FIFO, FEFO, or other user-defined picking rules, and provides directed put-away based on user-defined rules.

Our warehouse management system (WMS) has a lookup functionality that enables users to run queries by location, part number or container, and scan containers to make recommendations for location based on defined put-away logic. It provides lot and serial level visibility and handling, and supports splitting and merging lots and/or containers. It also provides full physical inventory and cycle count capabilities. It is a complete out-of-the-box solution and can be used on a scanner or a tablet. Users can also extend the standard capabilities using our low-code configuration application.

Warehouse Supervisor Role

Warehouse Supervisor Role effectively addresses all key supervisor processes in a warehouse. It enables a supervisor with access to five main cockpits: Receiving, Picking (for both production and shipping), Inventory Lookup, Counting, and Prefixes Configuration. As a result, supervisors can manage warehouse activities, release orders, assign key material handling resources (people and/or equipment) and execute better control over duties associated with the warehouse. It provides a view of a single site and multiple warehouses, bins, and locations.

The filtering functions make it easier for a supervisor to view details of master and simple containers to optimize container and inventory creation. It provides visibility and control all the way down to the lot and/or serial level. It is a complete out-of-the-box solution and can be used on a tablet, desktop, or laptop. Users can also extend the standard capabilities using our low-code configuration application.

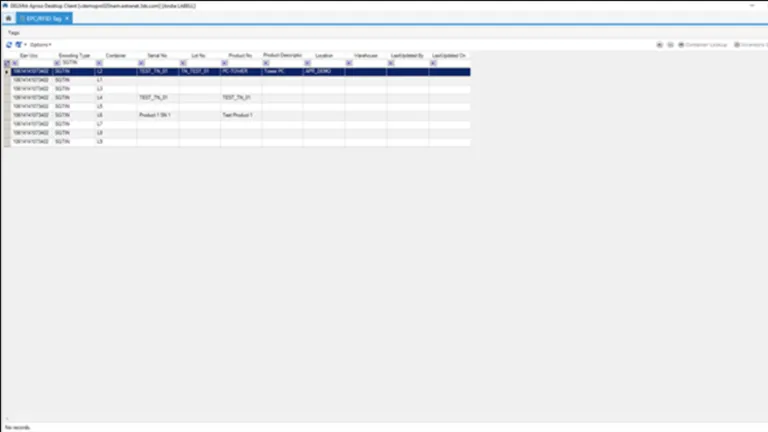

RFID

DELMIA Apriso RFID warehousing technology and tracking systems allow users to scan and track from anywhere inside your warehouse. Items are easily scanned and cataloged, enabling tags to be detected and read. Receiving, production, packaging, warehousing, and shipping are all integrated and highly automated on-site. The system sends the appropriate instructions to the packaging lines and monitors the results of each step, directing the appropriate disposition of the packed goods while providing full traceability.

The Virtual Twin Advantage for Warehouse Management System

DELMIA Apriso WMS software is included in both the product and production system's virtual twins, enabling users to model and simulate material flow to and from the line. This includes use of AMRs and other automated systems), material supply at the line, manual and robotic material handling, and multiple other WMS processes and resources. It ensures that proper equipment and material flows have been defined and tested virtually before they are implemented physically, saving significant time and cost, and avoiding potential issues that can occur when the physical layout and resources are put in place. For example, when a customer was adding a new robotic assembly line, they conducted their initial line layout.

DELMIA offered to create a virtual twin and test it before physical implementation. Our virtual twin identified an issue with one of the material handling robots; it could only reach 2/3 of the material on the pallet it was pulling from due to pallet location and robot reach limitations. Adjustments were made to the line virtually that not only solved the material reach problem, but also identified layout changes that improved throughput.

Key Benefits of Warehouse Management System Software

Enhanced Inventory Accuracy and Visibility

Provides real-time tracking and monitoring of all inventory movements, reducing errors, preventing stockouts and eliminating excess inventory costs through precise stock level management.

Data-Driven Decision Making

Leverage comprehensive analytics and reporting capabilities to identify bottlenecks, optimize processes and make informed decisions that drive continuous improvement across your warehouse operations.

Streamline Warehouse Operations

Automate and optimize key warehouse functions including receiving, put-away, material movement, picking, production line replenishment, shipping and counting.

Improve Production Synchronization

By integrating warehouse operations with production processes in real-time, our WMS ensures just-in-time material delivery, minimizing production delays and maximizing manufacturing throughput. Unlike standalone WMS solutions, our system synchronizes inventory management with production processes, creating a unified workflow that significantly improves manufacturing efficiencies and inventory accuracy.

Increase Labor Productivity

The intuitive mobile interface provides clear tasks and direction to operators for all key warehouse activities, improving worker efficiency and reducing training time for new employees. The synchronization with production helps ensure the operators are seeing only the tasks they need to perform, only when they’re needed, reducing material handling time and cost.

DELMIA Apriso helps us in building a production traceability platform to improve management efficiency and information transparency.

Start Your Journey

The world of warehouse management system is changing rapidly. Discover how to stay a step ahead with DELMIA Apriso Warehouse Management System software.

FAQ about Warehouse Management System Software

Also Discover

Learn What DELMIA Can Do for You

Speak with a DELMIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right DELMIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering